Progressing cavity pumps, commonly referred to as PC pumps, are essential in various industrial applications, from chemical processing and wastewater management to food production and oil extraction. Their ability to handle viscous fluids, abrasive slurries, and shear-sensitive materials makes them versatile and highly reliable. However, like all mechanical equipment, the longevity and performance of progressing cavity pumps depend on proper maintenance and operational care.

This guide explores key maintenance strategies that can significantly extend the lifespan of your PC pump, minimize downtime, and optimize overall system efficiency.

Understanding Progressing Cavity Pumps

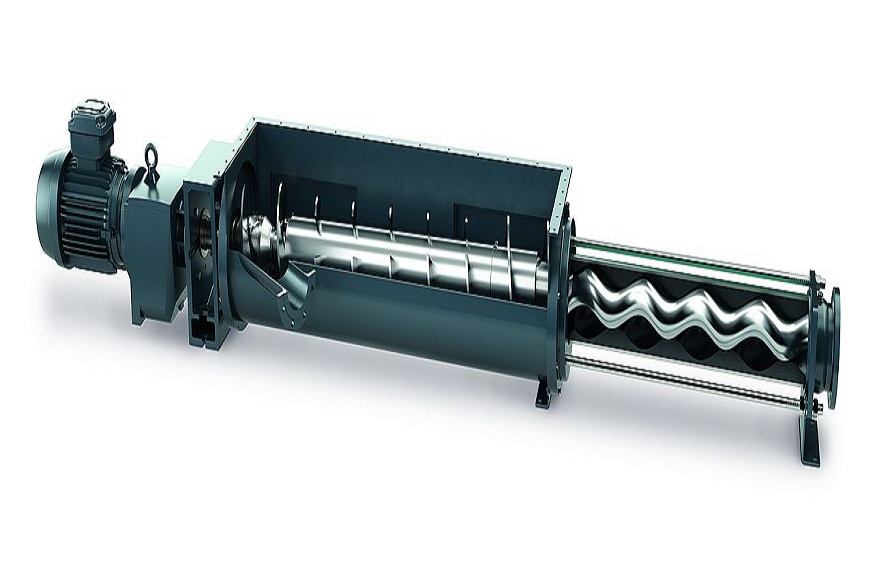

Progressing cavity pumps are positive displacement pumps that move fluid through a sequence of cavities formed between a helical rotor and a stator. As the rotor turns, it creates a continuous flow that is smooth, low-pulsation, and capable of handling thick or abrasive fluids.

Key characteristics of PC pumps include:

- Gentle pumping suitable for shear-sensitive fluids

- Ability to handle viscous and heterogeneous materials

- Smooth, consistent flow with minimal pulsation

- Reliable operation across various industrial processes

Due to these capabilities, progressing cavity pumps are widely used in industries such as wastewater treatment, food processing, oil and gas, and chemical manufacturing. Proper maintenance ensures that these pumps maintain their precision and reliability over time.

Key Maintenance Tips for Progressing Cavity Pumps

1. Regular Inspection and Monitoring

Frequent inspections are critical to identify early signs of wear or failure. Operators should rnsors or temperature gauges, can enhance early detection of potential problems.

2. Maintain Proper Lubrication

Lubrication is vital to the longevity of PC pumps, particularly for bearings and drive components. Insufficient lubrication can lead to increased friction, wear, and premature failure.

- Check and refill oil levels regularly according to manufacturer specifications.

- Use recommended lubricants that match operational requirements, including temperature and load conditions.

- Inspect seals and fittings to ensure no leakage or contamination occurs.

Proper lubrication reduces mechanical stress, improves efficiency, and extends the life of moving components within the pump.

3. Monitor and Maintain Stator and Rotor Condition

The rotor and stator are the heart of a PC pump. Wear in these components can compromise pump performance, leading to reduced flow, pressure loss, and excessive vibration.

- Inspect the stator for swelling, cracking, or signs of chemical attack.

- Check the rotor for surface wear, corrosion, or deformation.

- Ensure the rotor-stator fit is correct to maintain efficiency and minimize leakage.

Regular replacement or refurbishment of worn components prevents further damage and maintains optimal pump operation.

4. Keep the System Clean

Contaminants such as grit, debris, or sediment can accelerate wear in progressing cavity pumps. Maintaining a clean system protects internal components and improves pump efficiency.

- Install filtration systems to prevent solid particles from entering the pump.

- Flush the pump and pipeline regularly to remove accumulated material.

- Avoid introducing foreign matter during maintenance or fluid replenishment.

A clean system minimizes abrasion on the rotor and stator and reduces the risk of clogging or operational interruptions.

5. Monitor Operating Conditions

PC pumps are designed to operate within specific limits for pressure, flow, and temperature. Operating outside these parameters can lead to premature wear or catastrophic failure.

- Maintain operating pressures within the recommended range to prevent overloading.

- Avoid excessive speeds that can cause mechanical stress or heat buildup.

- Monitor fluid temperature to prevent damage to stator material and seals.

Using proper instrumentation to monitor these conditions ensures that the pump operates safely and efficiently under all scenarios.

6. Maintain Seals and Connections

Seals, couplings, and other connections are prone to wear and can cause leakage if not properly maintained. Leaks not only reduce pump efficiency but can also contaminate the fluid or surrounding equipment.

- Inspect mechanical seals regularly for wear or misalignment.

- Ensure all couplings and fasteners are properly tightened.

- Replace damaged or worn seals promptly to maintain system integrity.

Proper seal maintenance protects both the pump and the surrounding environment while ensuring consistent performance.

7. Plan for Preventive Maintenance

A structured preventive maintenance program is one of the most effective ways to extend the life of a progressing cavity pump. This involves scheduled inspections, routine lubrication, component replacements, and performance checks.

- Create a maintenance calendar based on operating hours and environmental conditions.

- Record maintenance activities to track component wear and predict replacement needs.

- Train operators and technicians in best practices for PC pump care.

Preventive maintenance reduces unexpected downtime, extends pump life, and lowers overall operational costs.

Additional Tips to Maximize PC Pump Longevity

- Proper Installation: Ensure that the pump is installed according to manufacturer guidelines, including alignment, support, and piping considerations. Incorrect installation can accelerate wear and reduce efficiency.

- Avoid Dry Running: PC pumps rely on the pumped fluid for lubrication. Running the pump dry can cause immediate damage to the rotor, stator, and seals.

- Use Compatible Materials: Ensure that the pump’s stator, rotor, and seals are compatible with the fluid being pumped to prevent chemical degradation.

- Regular System Checks: Monitor associated equipment such as drive motors, gearboxes, and instrumentation to maintain overall system reliability.

- Temperature Management: Avoid operating in extreme heat or cold without proper monitoring, as thermal expansion or contraction can impact component fit and performance.

Common Applications of Well-Maintained Progressing Cavity Pumps

- Wastewater Treatment: Handling sludge, slurry, and other viscous fluids.

- Food and Beverage Industry: Gentle pumping of shear-sensitive products such as sauces, chocolate, or yogurt.

- Oil and Gas: Transfer of crude oil, emulsions, and viscous hydrocarbons.

- Chemical Processing: Handling abrasive or corrosive chemicals with precision.

- Construction and Mining: Moving slurry, cement, or other viscous materials.

In all these applications, the longevity and reliability of PC pumps are closely tied to proper maintenance practices.

Progressing cavity pumps are versatile and reliable solutions for handling viscous, abrasive, and shear-sensitive fluids. However, their long-term performance depends heavily on proper maintenance. Regular inspections, lubrication, monitoring rotor and stator condition, maintaining seals, and adhering to operating guidelines are all critical steps in extending pump lifespan.

A proactive preventive maintenance approach minimizes downtime, reduces repair costs, and ensures consistent performance across a wide range of industrial applications. By following these best practices, operators can maximize the efficiency, reliability, and longevity of their progressing cavity pumps, ensuring smooth operation for years to come.